Prem Fixer

Your Trusted Partner for Custom Fasteners & CNC Machining Solutions

Prem Fixer – Premium Precision Fasteners (Your Trusted “Fixer” for Secure Connections) & CNC-Integrated Manufacturing Partner, Delivering One-Stop “Fix” for Custom Metal/Plastic Parts from Prototype to Mass Production.

Core Strength: Custom Fasteners | One-Stop Custom Plastic & Metal Parts Services (CNC Machining, Sheet Metal Fabrication, 3D Printing) From Prototyping To Mass Production.

- Cost Save 30% On Average

- Fast Global Delivery Within 3 Days

- 15+ Years Global Market & Design Experience

We solemnly guarantee

: All uploads files are safe and confidentia

CERTIFICATIONS :ISO 9001:2015

Trusted by

About Us

Prem Fixer

China-Based Manufacturer: Fasteners & Precision Custom Parts

“PremFixer (Guangdong Pinshang Hardware Products Co., Ltd.) is a premier China-based manufacturer of precision fasteners and custom CNC parts. We are proudly certified to ISO 9001:2015

Since 2020, we have evolved into a strategic supplier for high-end OEMs in the Bicycle, Automotive, Aerospace, Medical, and Industrial sectors. We consistently meet rigorous global demands by delivering close-tolerance components, competitive pricing, and reliable delivery with uncompromising quality.”

15 +

Years of experience

30 +

Countries Shipped

2 000 +

Customers Served

2 500 000 +

Parts Manufactured

Prem Fixer

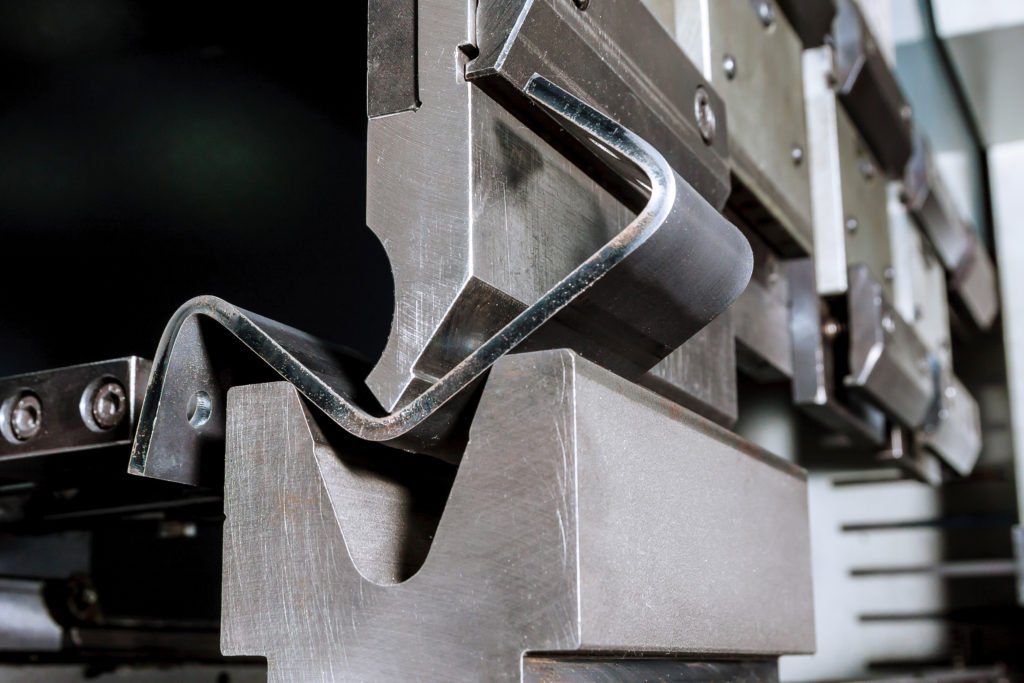

Custom Parts Manufacturing Capabilities

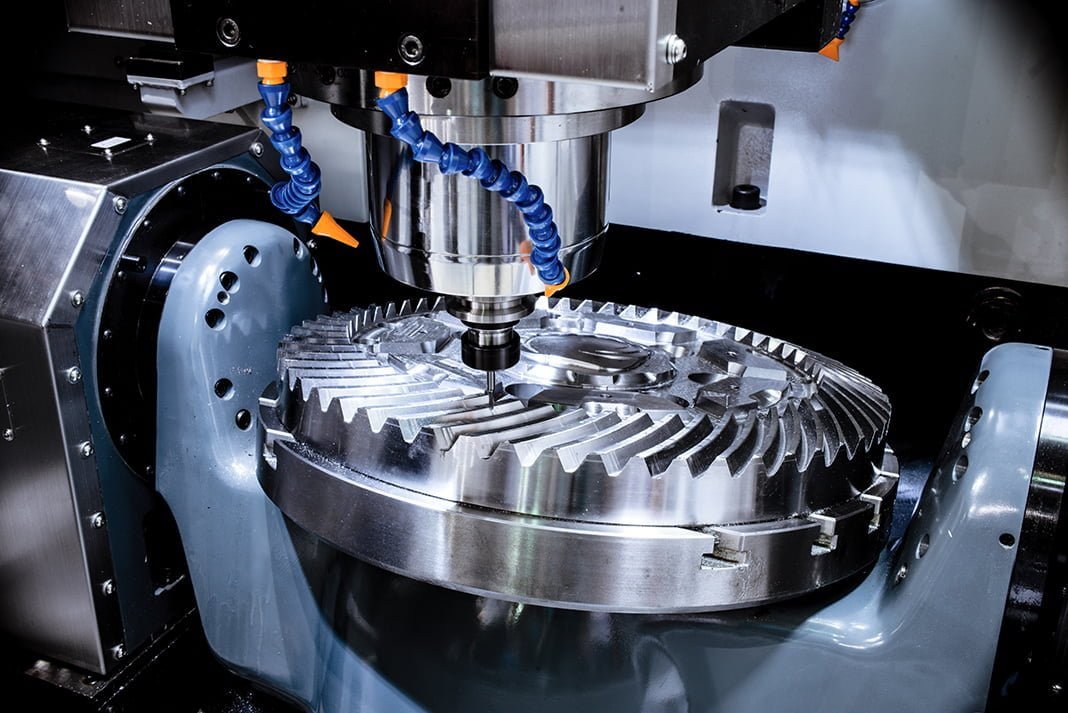

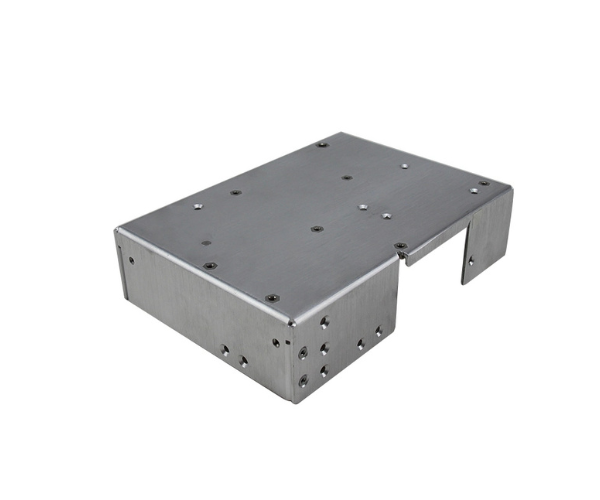

CNC Milling Services

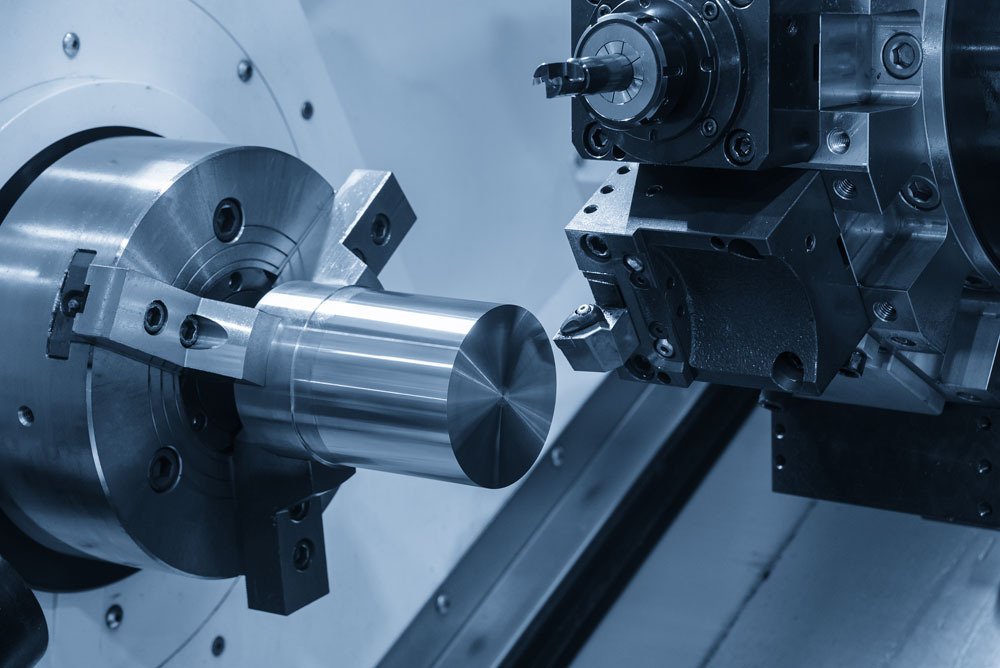

CNC Turning Services

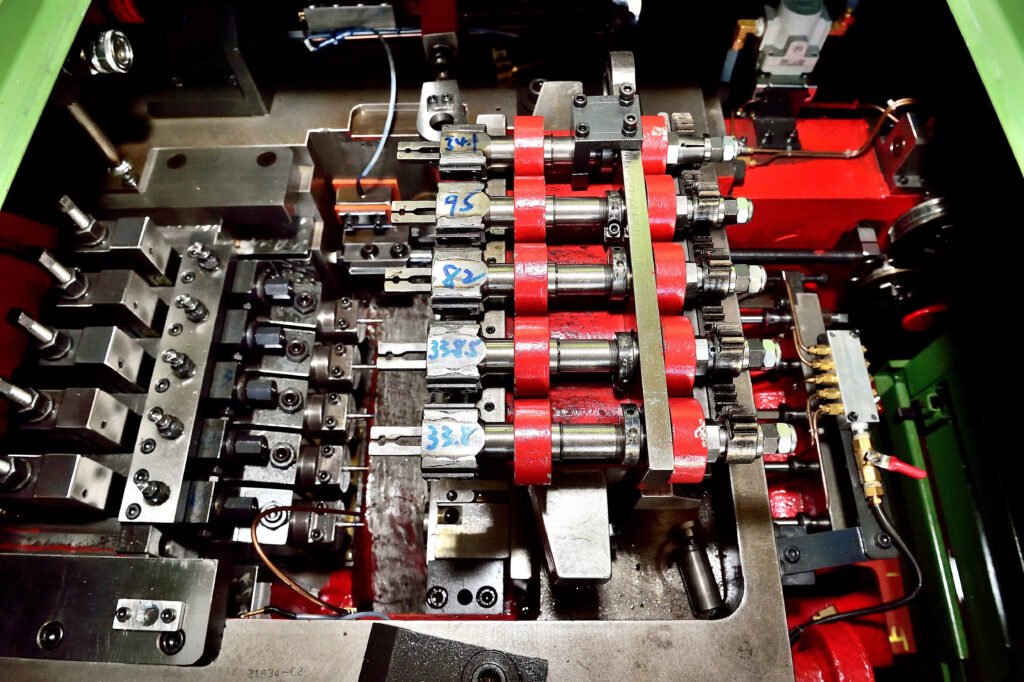

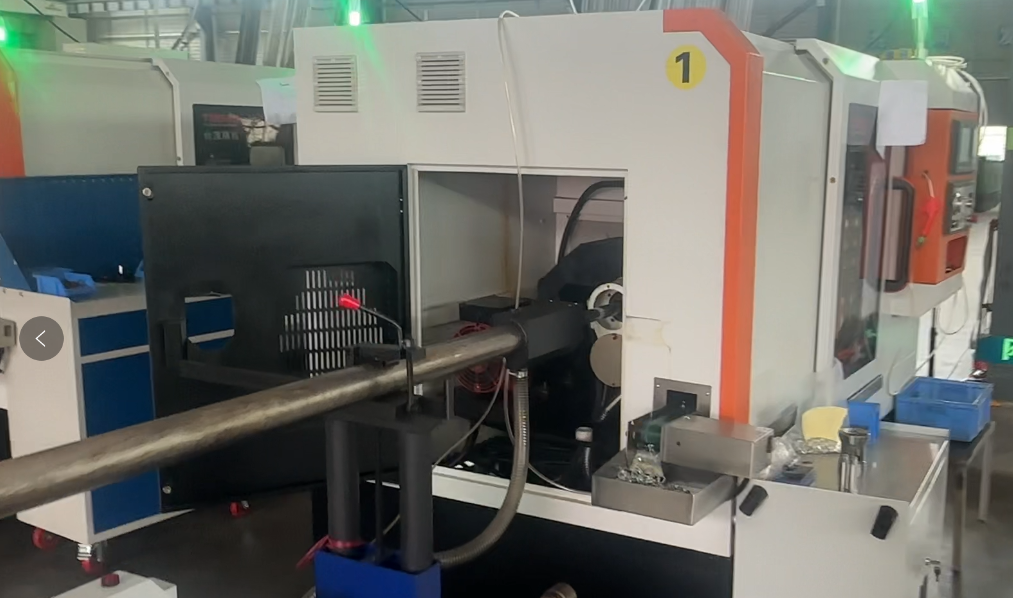

Fastener Cold Heading

3D Printing Services

Surface Treatment

Sheet Metal Materials

One-Stop Custom Manufacturing Solution

“At PremFixer, we deliver scalable manufacturing solutions—from Rapid Prototyping for design validation to Mass Production of end-use products. We specialize in tailoring our process to your needs, focusing on premium fasteners and high-precision custom parts.”

Rapid Prototyping Services

Rapid Prototyping & Product Development: We transform your CAD designs into tangible parts via CNC Machining, Metal/Plastic 3D Printing, and Sheet Metal Fabrication. With an MOQ of just 1 piece, we support rapid design iteration, functional testing, and engineering validation to accelerate your time-to-market.

Scalable Production Solutions

Low-Volume to High-Volume Production: PremFixer is your scalable manufacturing partner in China. We offer flexible solutions to bridge the gap between prototypes and mass production. Our engineering team ensures that whether you need 50 or 50,000 units, all custom parts meet strict accuracy and quality standards.

Cold Heading Fasteners

Custom Fastener Cold Heading: Optimized for high-volume manufacturing, our cold heading process delivers superior cost efficiency and material utilization. We ensure a stable mass supply of high-precision fasteners, bolts, and screws tailored to specific industry requirements.

Quality Assurance & Compliance

Precision Quality Inspection: We mitigate manufacturing risks through comprehensive DFM Analysis, rigorous Incoming Material Inspection, and detailed OQC Reports. Experience total transparency with real-time data sharing, securing reliable quality for every shipment.

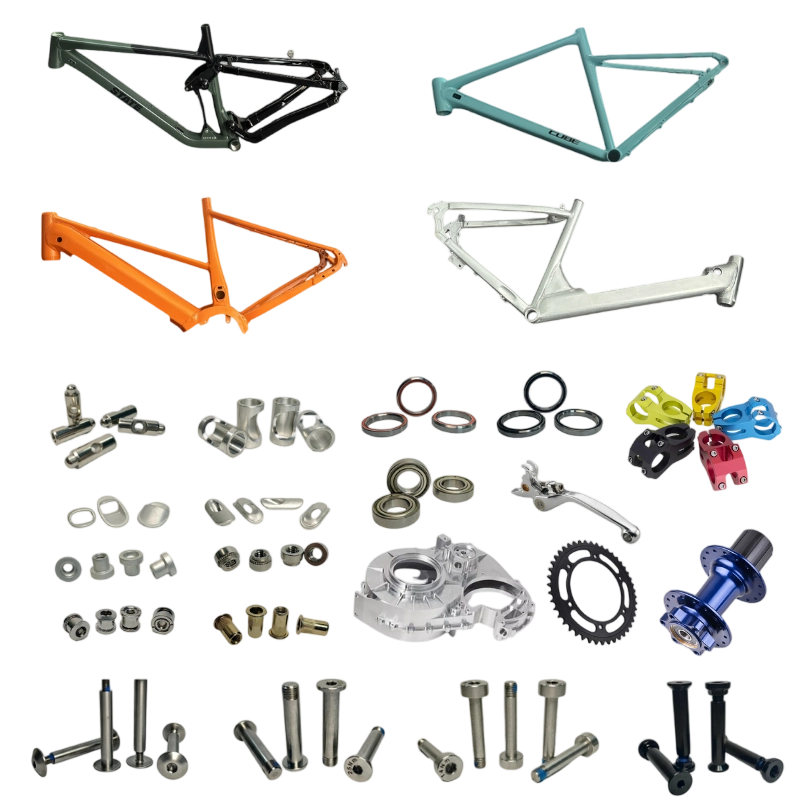

Industries we serve

“Serving Global Industries with Precision Manufacturing. PremFixer has delivered exceptional custom machined parts to over 2,000 clients worldwide. We provide industry-specific solutions, ranging from ISO 13485 medical device components and aerospace hardware to high-performance bicycle & motorcycle parts. Our expertise also covers electronics enclosures, industrial robotics, marine equipment, and telecommunications.

Backed by strict quality standards, we ensure every custom part perfectly meets the unique demands of your sector. Choose PremFixer as your reliable partner to elevate your business.”

Materials Which We Commonly Used

PremFixer can manufacture your prototypes and production parts from a vast array of high-quality materials sourced globally. We also accept customer-supplied materials to meet your specific project requirements. Below are the materials we commonly process:

Metal

Expert machining of Aluminum (6061/7075), Stainless Steel (303/304/316), Brass, Copper, Bronze, Mild Steel, Titanium, Magnesium, and Molybdenum.

Plastic

Precision machining for ABS, POM (Delrin), PEEK, Nylon (PA), PTFE (Teflon), PC, Polyethylene, PMMA (Acrylic), HDPE, and Garolite G-10.

Carbon Fiber

Extremely strong and lightweight with excellent fatigue resistance, making it ideal for aerospace and high-performance applications.

Ceramics

Known for high hardness and chemical stability. We process Alumina, Zirconia, Silicon Nitride, and Silicon Carbide.

Superalloys

High-performance nickel, cobalt, and iron-based alloys (like Inconel) known for exceptional mechanical strength and oxidation resistance in extreme environments.

Kovar Alloy

A nickel-cobalt ferrous alloy tailored for unique thermal expansion properties, closely matching hard glass and ceramics for electronic packaging.

How To Work With Us

Streamlined Manufacturing Process in 4 Simple Steps. To save you time and cost, PremFixer has simplified the entire workflow. From rapid prototyping to the final delivery of custom parts, we ensure a seamless experience that accelerates your time-to-market.

Send Us Design

Click any quote button on our website, fill in your requirements and upload the drawings.

Quote Analysis

Our engineers will analyze how to improve the parts and then provide you with the best prices.

Order Confirmed

After you confirm the quote, samples will be sent for approval, then bulk will be made.

Get your Goods

Custom precision parts undergo our QC inspection with flexible shipping via sea, air, or rail.

Different Surface Finish Types We Offer

PremFixer provides 20+ types of precision surface finishes to enhance the performance and value of your on-demand machined parts. Whether you require superior corrosion resistance, improved wear durability, or a specific aesthetic appeal, we deliver the right post-processing solution. Explore the common finish types we utilize for custom manufacturing:

As-Machined

Smooth

Brushing

Black Oxide

Chromating

Electroplating

Passivation

Powder Coating

Polishing

Heat Treating

Anodizing

Electropolishing

Sandblasting

Laser Engraving

Tumbling

Bead Blasting

Why Choose Prem Fixer

As a premier custom manufacturer, PremFixer provides ‘made-to-order’ manufacturing solutions designed to fit seamlessly into High-Mix Low-Volume (HMLV) production strategies. We specialize in producing complex precision machining parts and components at any volume—from single prototypes to full-scale runs. PremFixer’s engineering team is ready to respond swiftly to your needs, ensuring your projects are both efficient and cost-effective.

7*24 Engineering Support

PartMFG 7*24 Engineering support allows for immediate, on-demand problem resolution. We provide detailed design support to enhance your custom parts for manufacturability.

Competitive Price For You

Savings 30-50% cost compared with your local manufacturer and market, this is based on our optimized production processes and stringent cost management.

Rapid Turnaround Time

PremFixer boasts an exclusive fast logistics network, ensuring prompt delivery of both express and bulk shipments to most countries worldwide within 3 days.

15+ Years Experiences

PremFixer boasts 15+ years of design and export expertise across global markets—especially the USA and EU—with long-standing partnerships with numerous global enterprises.